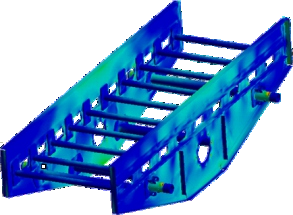

Step Screen

| Categories | Step Screen |

|---|---|

| Brand | Harden |

| Model | SZS-S2060 |

| Terms of Payment | L/C, T/T |

| Update Time | Apr 18,2025 |

Detail Information

Step Screen

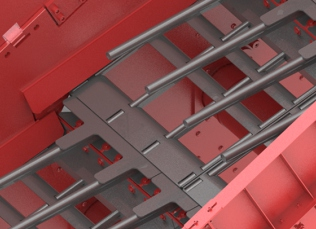

The step vibrating screen is based on the principle of mechanical vibration.

The exciter provides the excitation force to drive thescreen plate to vibrate in a circle.

The materials are stratified and transported under the vibrating projection of the screen machine.Materials smaller than the mesh size fall down and are transported, which is complete particle size classification.

Product Parameter

|

Driver Power (kw)

|

Screening Area

|

Capacity (m³/h)

|

Machine Dimension (mm)

|

Machine Weight (t) |

|

45

|

2000*6000

|

80-100

|

7800*4200*5600 |

13 |

Product Features

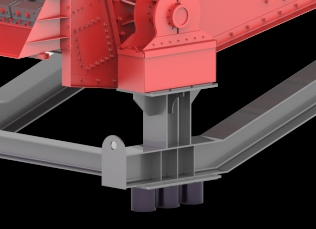

Secondary lsolation

The impact on the screen box is reduced, the vibration transmission to the ground is smaller, and the service life of the equipment is longer.

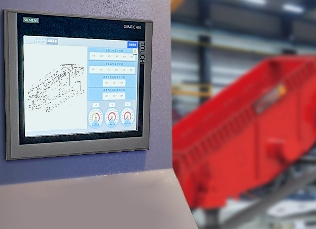

Convenient Adjustment

According to the material characteristics,vibration parameters can be quickly adjusted on-site.

Thin Oil Lubrication

The exciter bearing adopts double sealing and thin oil lubrication. which effectively extends the bearing life and makes maintenance easier.

Performance Optimization

Special instruments are used to monitor and adiust various performance indicators before leaving the factory to ensure that the equipment reaches optimal operating status.

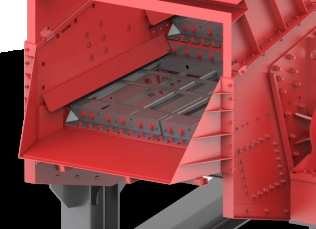

Modular Design

The structural components are modular,which facilitates maintenance and replacement and can be flexibly adjusted according to the production line. Different forms of screens can also be replaced according to material characteristics

Bulky Waste Handling

The larger opening and specially designed screen mesh are especial suitable for pre-screening of large-sized waste,while minimizing the possibility of missed selection,incorrec selection and clogging of stuck waste and improving screening efficiency.

Structural Optimization

The reinforced screen machine structure improves vibration fatiquelife and overall reliability. The finite element method isused to make the structural design more reasonable, avoid resonance,and have better stability.

Smooth Start And Stop

Minimize start-stop shaking and reduce instantaneous impact on the screen machine and foundation. At the same time,the starting current of the motor is limited to reduce the power supply pressure of the factory.

Typical Application Range

Waste Plastic & Film

Industrial Waste

Construction Waste

Waste Battery

MSW

Biomass

Cutomized Your Solution

- *Name

- Tel

- *Title

- *Content