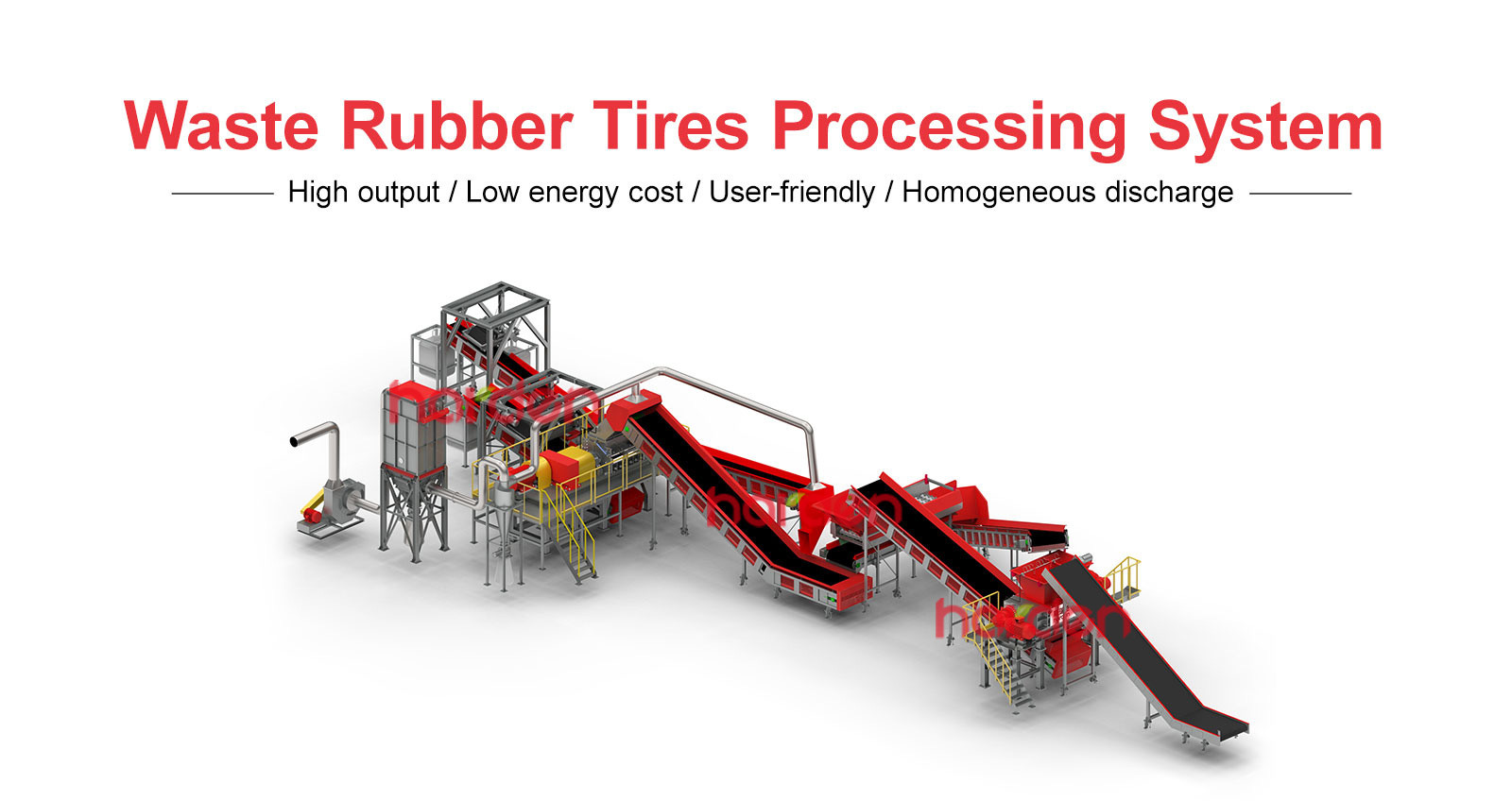

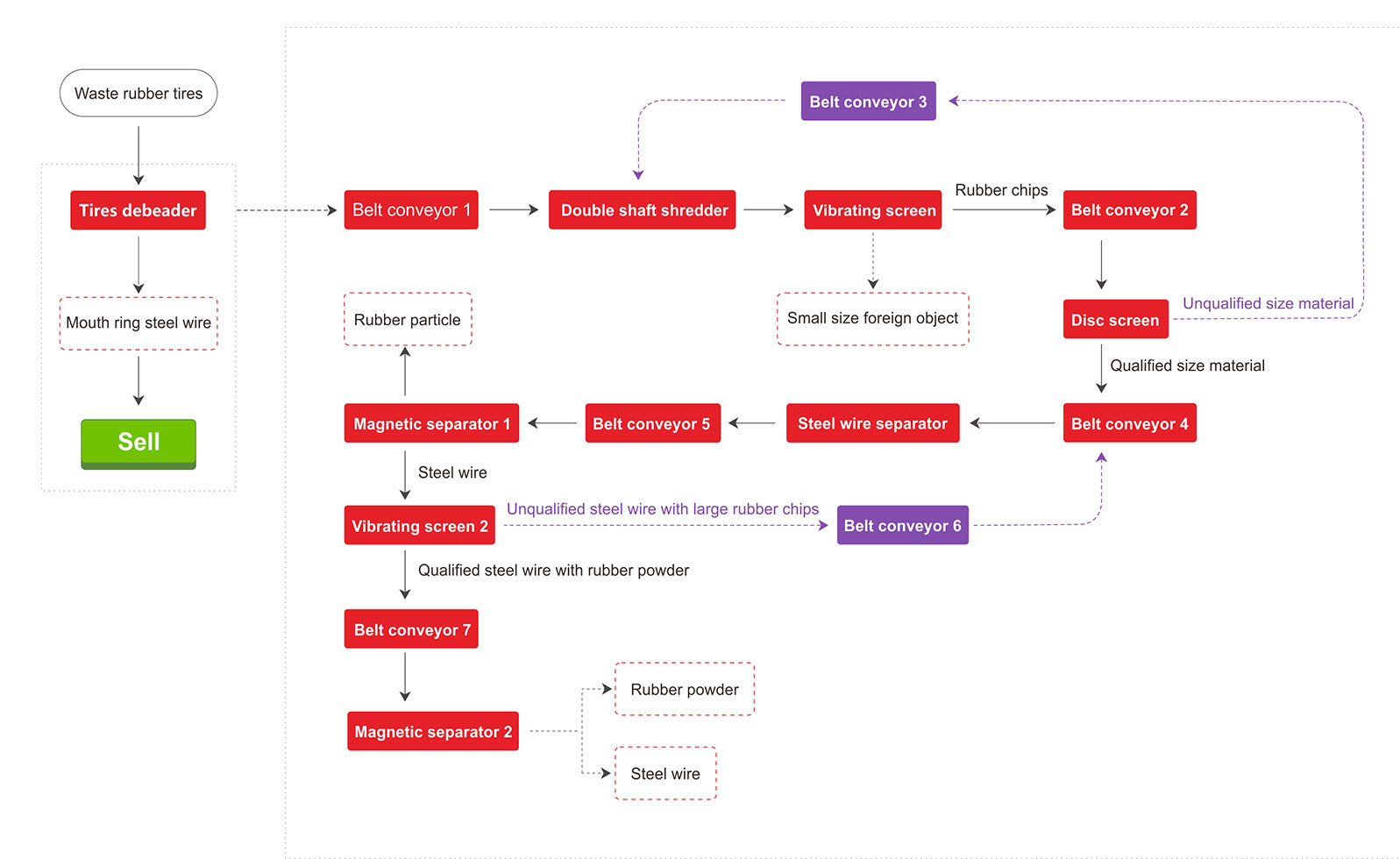

Waste Rubber Tires Processing System

Recycling of steel wire

The sieved steel wire has a rubber content of less than 1% and can be smelted into steel shots, which can be used for sand removal and rust removal of castings.

Auxiliary fuel

The calorific value of tires is more than 8000 kcal. Most high-heat industries such as cement plants, power plants, can use waste tires as alternative fuels, thereby reducing production costs.

Rubber regeneration

The crushed rubber powder can be widely used in highways, airplanes/sports runways, flame-retardant materials, rubber and plastic bottoms, waterproof materials and other fields.

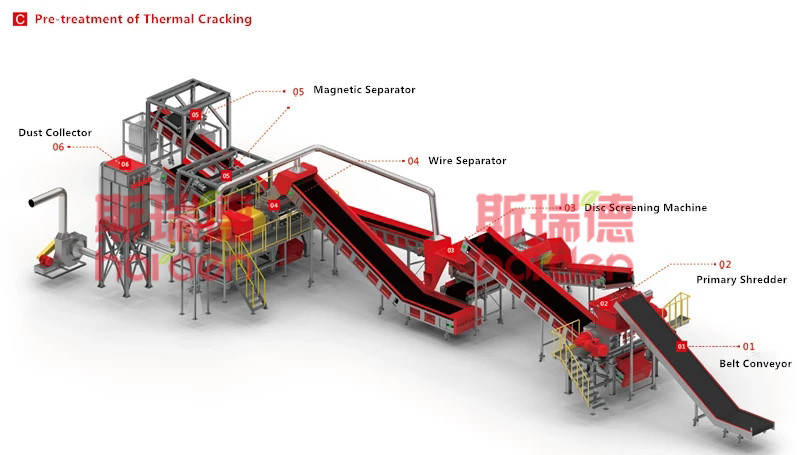

Thermal pyrolysis

After tire crushing, the mixed oil produced by the condensation and the non-condensable combustible gas can be used for fuel-burning power generation.the separated coarse carbon black can be for commercial application.

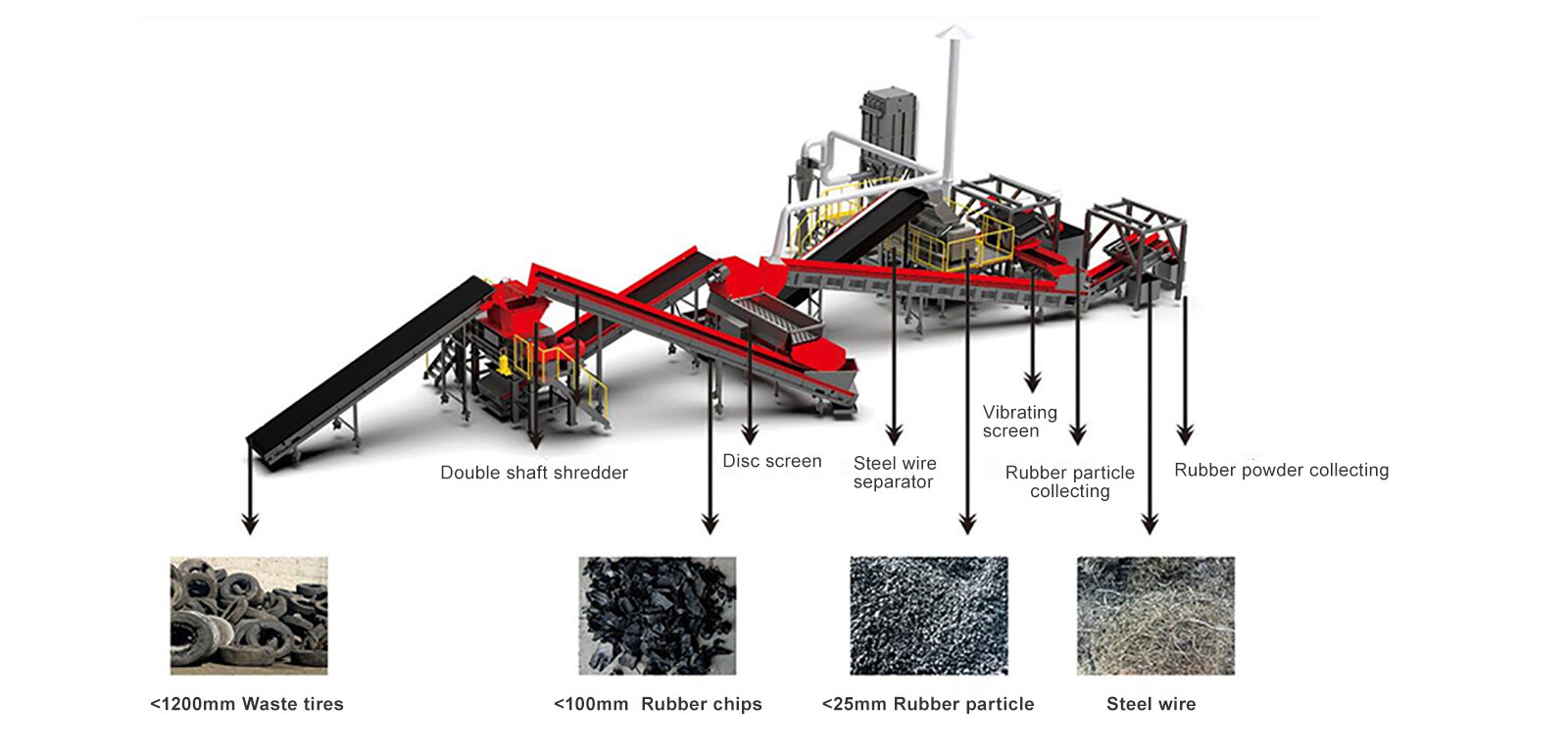

Double shaft shredder

Stable operation / Imported knives from Europa / Low maintenance cost

Disc screen

High wear resistant alloy material / Adjustable capacity

Steel wire separator

Knives with adjustable direction / Repairable knives

Magnetic separator

Effectively removing metal / Prevents the leakage of the dust

Dust separator

Effectively remove the dust produced from the system / Excellent sealing performance / Low energy cost

Slat conveyor

Anticorrosive material / Remote start and stop, emergency stop / Intelligent overloading protection

Remote data analysis

Central database / Automatic expert system for fault diagnose / Message reminder and warning system

Electrical control system

Automatic operation / Sound-light alarm / Fault visualization / Real time monitoring