Biomass Co-Firing: Unlocking a Low-Carbon Future for Sustainable Development

Biomass co-firing refers to the method of partially replacing coal with biomass in coal-fired boilers for power generation. It utilizes the advantages of biomass as a renewable energy source while simultaneously reducing coal consumption, thus lowering greenhouse gas emissions.

With growing global attention on reducing greenhouse gas emissions, biomass co-firing has gradually become a widely accepted low-carbon energy technology. According to global energy development trends, biomass co-firing has significant market potential.

Many countries, particularly the United States and European nations, have already conducted pilot projects and applications of biomass co-firing in large coal-fired power plants. In the future, with technological advancements and policy support, the application of biomass co-firing is expected to expand further, with widespread deployment anticipated by 2030.

Benefits of Biomass Co-firing

Reduction of Carbon Dioxide Emissions

Biomass is considered a carbon-neutral fuel since the carbon dioxide released during combustion is part of the atmospheric carbon cycle. When used as a fuel, its carbon emissions are viewed as relatively neutral. Compared to pure coal combustion, co-firing biomass can significantly reduce carbon dioxide emissions. Many studies have shown that greenhouse gas emissions can be reduced by 5% to 18% when biomass is combusted with coal, depending on the proportion of biomass used.

Reduction of Pollutant Emissions

In addition to reducing carbon dioxide emissions, biomass co-firing can also effectively reduce the emissions of other pollutants. Due to lower sulfur content in biomass compared to coal, co-firing biomass can decrease the emission of sulfur dioxide (SOx). Additionally, the lower nitrogen content in biomass can effectively reduce the generation of nitrogen oxides (NOx), thereby minimizing acid rain formation. Research indicates that in certain demonstration projects, NOx emissions from biomass-coal co-firing have been reduced by approximately 30%.

Economic Benefits

Another significant advantage of biomass co-firing is the reduction of fuel costs. In many regions, biomass is a cheap and renewable fuel source, and its unit heat cost is often lower than that of coal. This makes biomass co-firing an effective way to lower operational costs in power plants. For instance, the Tennessee Valley Authority in the United States estimates that co-firing with biomass fuel at its Colbert Plant can save approximately $1.5 million annually in fuel costs.

Provision of Sustainable Energy Supply

Biomass co-firing contributes not only to reducing dependence on fossil fuels but also provides new business opportunities for agriculture and forestry sectors. Especially, agricultural residues and forestry waste can serve as fuel sources, mitigating waste disposal and burning issues.

Technologies and Implementation Methods of Biomass Co-firing

The pathways and methods for biomass co-firing primarily include the following:

Direct Co-firing

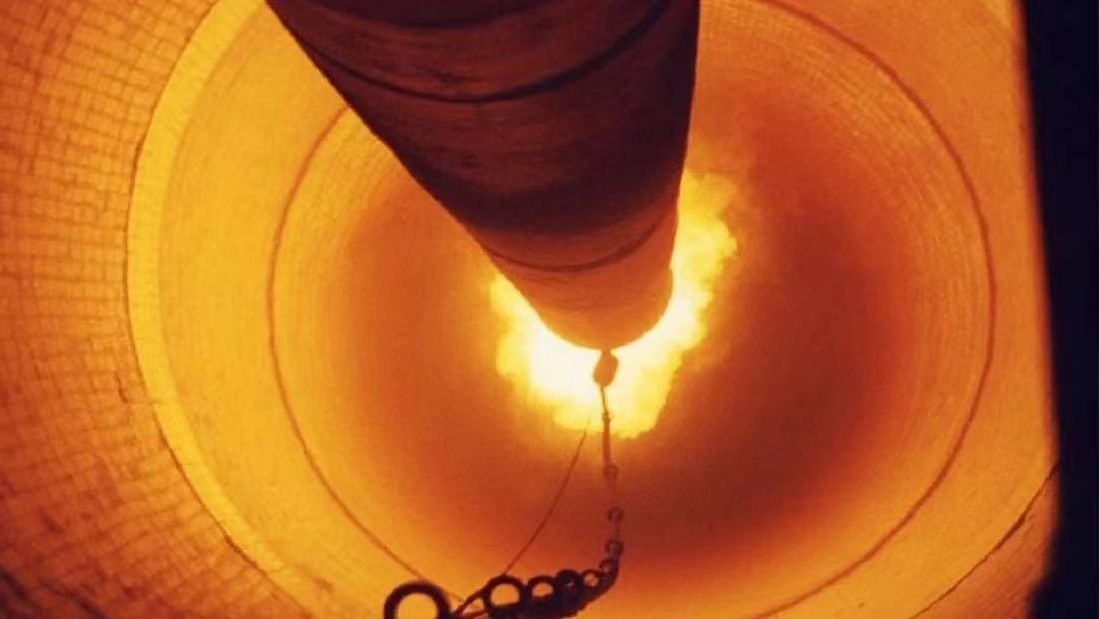

Direct co-firing is the least expensive, most straightforward, and most commonly used method. Biomass is processed in the same milling machines (crushers, hoppers, and pulverizers) as coal and is then directly fed into the boiler. Biomass can be mixed with coal at the fuel yard or sent into the combustion chamber separately. Multi-fuel fluidized bed boilers achieve efficiency rates exceeding 90%, and due to lower combustion temperatures, emissions are lower than those from traditional grate combustion.

Indirect Co-firing

In this method, biomass is first gasified, and the resulting fuel gas is burned in the main boiler. Sometimes, the gas must be cooled and cleaned, which poses more challenges and results in higher operating costs. However, this method offers high fuel flexibility.

Systems of this type have been implemented in several power stations, such as the Zeltweg plant in Austria, the Lahti plant in Finland, and the AMER-8 plant in the Netherlands. Since gasification is conducted separately, the ash produced from coal and biomass is separated.

More varieties of biomass fuels can be utilized, as potential issues related to different chemical compositions and physical characteristics of the biomass are addressed before the gas fuel enters the main combustion chamber, thus maintaining boiler efficiency.

Parallel Co-firing

Biomass is burned in a separate boiler to produce steam, which is then used alongside the primary fuel for power generation. Parallel co-firing is most popular in the pulp and paper industry, where dedicated biomass boilers are used for bark and waste wood. These industries save energy and improve energy efficiency by utilizing the biomass residues and by-products generated in their primary focus—paper production.

Importance of Pretreatment in Biomass Co-firing

Pretreatment plays a crucial role in biomass co-firing. Due to the often high moisture content and low heating value of biomass fuels, their combustion performance is generally inferior to that of coal. Therefore, appropriate pretreatment can significantly enhance their heating value and reduce instabilities during the combustion process.

Increase in Heating Value

Pretreatment can effectively lower the moisture content of biomass, which is essential for improving its heating value. The drying process is typically the most common form of pretreatment, significantly reducing the moisture content and stabilizing combustion performance.

Enhanced Combustion Stability

Pretreated biomass fuels can better mix with coal during combustion, improving combustion stability. Particularly in large-scale power plants, the design of the burners and the mixing ratio of fuels significantly influence combustion effectiveness. Pretreatment allows biomass to match up better with coal during combustion, avoiding incomplete or uneven burning.

Reduction of Ash Accumulation

Biomass fuels often result in substantial ash production, which can negatively affect boiler thermal efficiency and potentially damage equipment. By pretreating the biomass to reduce impurities and ash content, the amount of ash generated after combustion can be effectively minimized, thus enhancing boiler efficiency.

Biomass Pretreatment Technologies for Co-firing

After selecting biomass raw materials and co-firing pathways, biomass pretreatment technology becomes critical for successful biomass co-firing. Given the diverse origins and complex compositions of biomass raw materials, pretreatment is necessary regardless of the chosen co-firing pathway to improve efficiency and outcomes.

Harden Machinery RDF Biomass Resource Processing System

Harden Machinery has conducted various tests on different types of biomass, such as straw, waste bamboo, and branches, with varying moisture contents and humidity. They have continuously improved and optimized the equipment based on the principle of "finer shredding, faster separation, and more precise selection," resulting in a biomass resource processing system compatible with various biomass raw materials.

Harden's Project Case Studies

In a biomass gasification power project in Northeast China, corn, wheat, and rice straw were used as raw materials. Through precise processing techniques, various straw types were processed into biomass fuel with a particle size of less than 30mm and a soil and impurity content of below 5%, which was applied in anaerobic fermentation and gasification power generation.

The biomass co-firing project in a cement kiln in Southwest China utilized local agricultural and forestry waste materials, such as waste bamboo and straw, to prepare RDF alternative fuel for use in industrial kilns, replacing coal.

Biomass co-firing is gaining traction as a key energy solution, offering environmental, economic, and sustainability benefits. Ongoing advancements, especially in pretreatment technologies, will boost its efficiency and stability. The Harden biomass RDF solution, an advanced pretreatment method, shows significant potential in enhancing co-firing outcomes. In the future, biomass co-firing is poised to play a pivotal role in addressing global climate and energy challenges.