Harden Patented Cutter Shaft Design - Makes Material Crushing Easier and More Efficient!

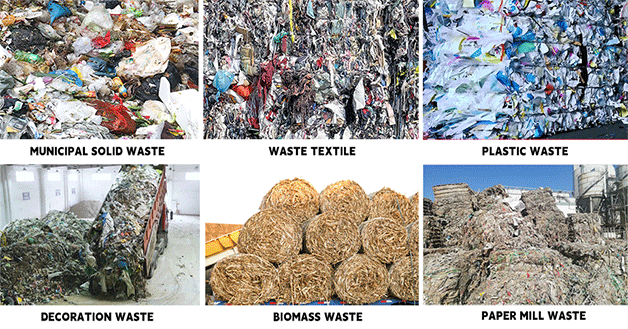

Harden Machinery Ltd. always focus on our customer’s need and the pain points of the market, our R&D team specially developed the SG series single-shaft shredder, which is used for various solid waste such as waste textiles, decoration waste, municipal solid waste, paper mill waste, waste plastics and biomass waste etc.

The SG single-shaft shredder is equipped with a stable and high-power reducer and a high-speed cutter shaft to squeeze and shred materials.

Its great power unit and the close-packed shredding cutter shaft patented by HARDEN can greatly improve the cutting efficiency of materials.

Its strong stability and guaranteed tool quality convince our users.

How does the SG single-shaft shredder meet customers' need for high quality and high capacity?

· High-efficiency and large-capacity shredding

The close-packed crushing cutter shaft independently developed by the Harden team increases cutting efficiency by 50%.

·Intelligent built-in arc pressing technology

Intelligently adjusts the pressing speed according to the spindle load; Intelligently determines the material condition to adjust the pressing stroke; Anti-jamming mechanisms equipped at the front and rear.

·Specially equipped screen to ensure shredding granularity

Hydraulic drive, saving time and effort; multi-piece structure and single-piece screen are lightweight and easy to disassemble and install; and hexagonal screen holes increase the material passing area.

·Safety operation is the first principle

The equipment has passed CE safety certification. If an unbreakable object enters or the door is not closed,

The equipment will automatically shut down.

Whether it is leather fabrics with higher flexibility or light materials with lower density, the SG series single-shaft crusher can meet the needs of customers with superior processing effects.

Our Customer Cases

Case1 Company A in Southeast Asia—Municipal Solid Waste (MSW Alternative Fuel Preparation System:

The project aims to convert millions of tons of municipal solid waste stored locally into RDF alternative fuel with high calorific value through multiple solid waste treatment technologies, thereby reducing land pollution caused by landfills.

This project was applied to Harden SG series shredders The previously treated light combustible substances are finely shredded and finally prepared into high calorific value alternative fuels with a particle size of <50 mm for cement kiln combustion.

The entire production line can process nearly 50 tons of MSW per hour.

Watch the video:

https://youtu.be/510dAahJ_W8?si=uw2NWgVJoIQqPyEs

Case2 Company B——Decoration Waste Alternative Fuel Preparation System

The project aims to sort and shred decoration waste with complex compositions to ultimately obtain purer RDF/SRF alternative fuel. The entire production line has a processing capacity of 20 tons per hour.

The customer used a Harden SG series single-shaft shredder in the fine-shredding process to crush the combustible materials into RDF alternative fuel with a particle size of less than 50mm and transport it to the cement plant as fuel.

More details about our product:

https://www.hardenshredder.com/SL-Series-Single-Shaft-Shredder.html

Follow our YouTube channel for more projects:

https://www.youtube.com/channel/UCrdi6BkuMAW242NMmQuagIg/videos?view_as=subscriber