Alternative Fuel Preparation Technology Used in Cement Industry

Under

the environment of global carbon emission reduction, cement production with low

carbon emission is an important direction of cement industry development.

How

to maximize the value of solid waste is the difficulty of effective utilization

of solid waste resources, and it is also a crucial process to replace fossil

fuels in cement kilns.

The

alternative fuel preparation system provided by Harden processes solid waste

into solid recovered fuel (SRF) or Refuse-derived fuel (RDF) with high

calorific value through shredding, magnetic separation, dust removal,

granulation and other processes. And the thermal substitution ratio (TSR)

reaches 60%-70%, which meets the basic demand of coal burning in cement kilns.

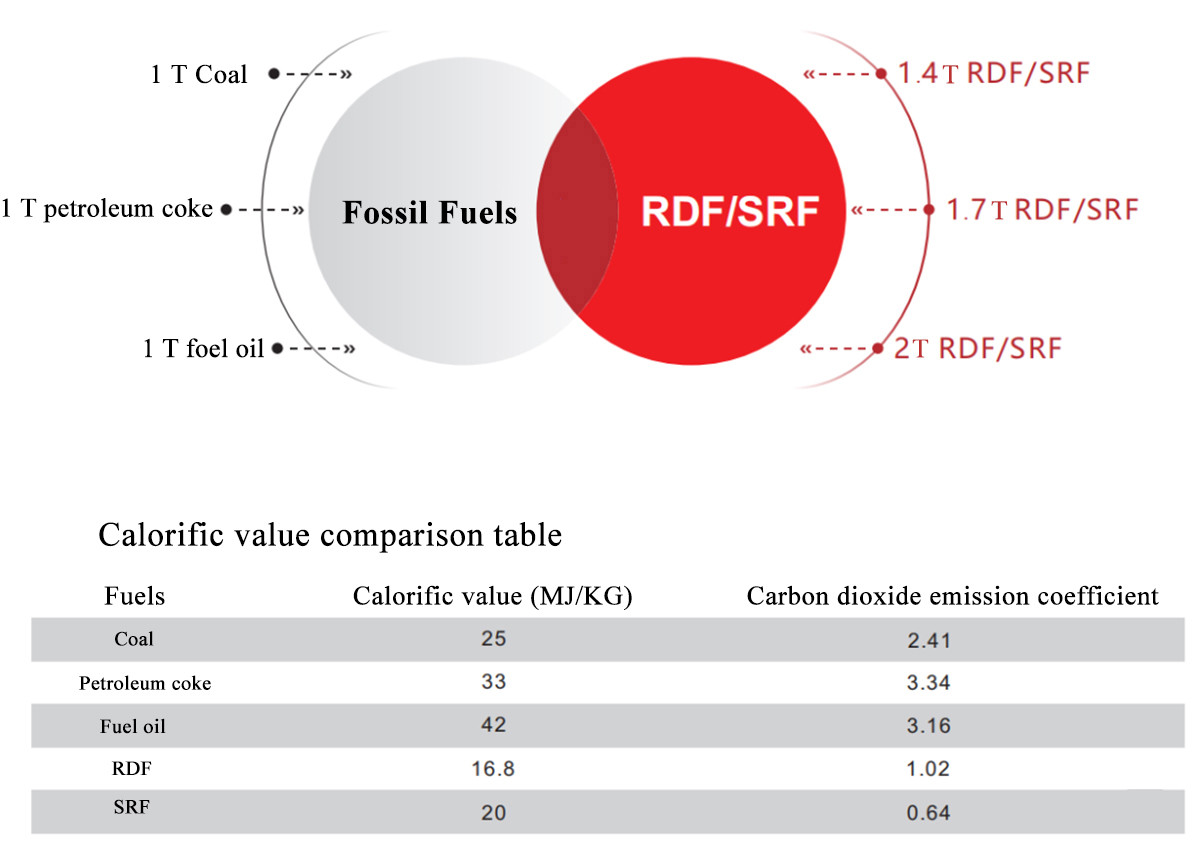

The

Substitution Relationship Between SRF/RDF and Coal

In

view of the complex composition of solid waste, Harden has conducted in-depth

analysis and developed mature SRF/RDF preparation systems in the fields of MSW,

industrial waste, bulky waste, paper mill waste, legacy waste, waste tires,

biomass waste, etc. Through the combination of modular and integrated

equipment, Harden provides the whole process of customization, manufacturing,

quality inspection, installation and commissioning and after-sales service.

Selected

Cases

Municipal Solid Waste (MSW) Recycling System

Industrial

Waste Recycling System

Biomass

Waste Recycling System

Waste

Tires Recycling System

Legacy

Waste Recycling System

Paper

Mill Waste Recycling System

Hazardous

Waste Pretreatment System

The

alternative fuel preparation system can not only solve the problems of complex

composition and low calorific value of solid waste, but also improve its

combustion efficiency per unit volume in cement kilns, so as to achieve a

higher TSR. By the system, the cement industry can gradually replace the use of

fossil fuels and achieve low carbon emission economy.