Leather and Textile Shredder in Waste Recycling

Two Main Sources of Leather and Textile Waste

1) At industrial level

Leather and textiles waste manufacturing processes like warp preparation, printing, finishing, weaving,dyeing, and quality and process control, generates lot of leather and textile waste during these process. Majority of leather and leather waste comes from industrial sources.

2) At household level

With the development of clothing consumption, plenty of old leather shoes, old clothes, and hats were discarded daily as they are worn out or even unfashionable or undesirable. Leather and textile from waste are the other main source of leather and textile waste.

Three Major Leather and Textile Waste Management

Leather and textile waste comprise natural cotton, animal fur, silk, linen, etc., may also be polyester, cotton, acrylic ,and other chemical products or artificial leather. Whether it is natural or chemical, there are three major ways to process leather and textile waste in the recycling industry currently,

Recycling: After being selected and shredded by specialized factory, leather and textile waste can be processed into vegetable greenhouse insulation, tree insulation blanket, roadbed fabric, car interior, sound insulation cotton, etc.

RDF (Refuse Derived Fuel) production: After shredded and secondary processed, leather and textile waste can be processed into RDF production for co-incineration use in cement plant calciners, fluidized bed combustion, and power plants for energy recovery.

Pyrolysis is treatment: Pyrolys is technology that can be used to process leather and textile waste to obtain combustible gases, liquids , and other useful substances. However, whether it is for distillation, pyrolysis at low temperature, pyrolysis at medium temperature , or pyrolysis at high temperature, it is required that the material should reach a certain particle size so as to ensure the pyrolysis process is carried out fully.

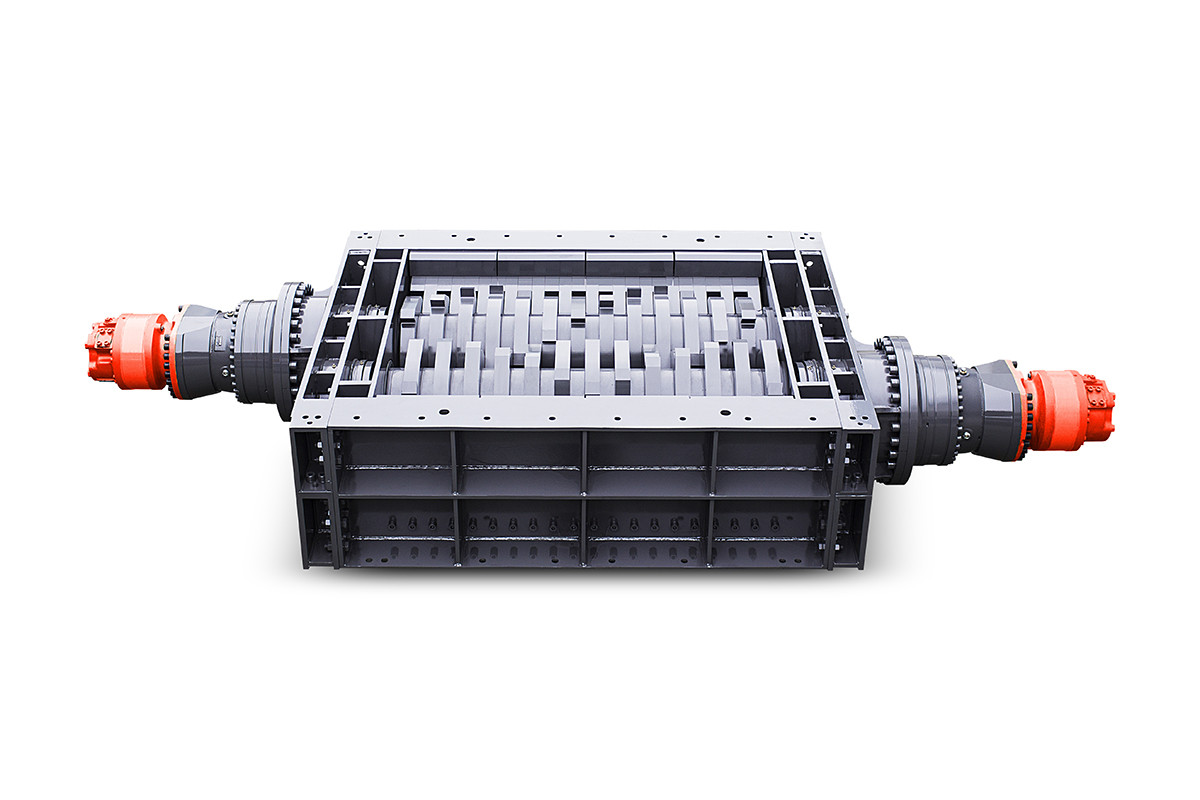

Two Shaft Shredder and Single Shaft Shredder in Leather and Textile Recycling

Shredding leather and textile waste into certain particle size is a key step to process leather and textile waste. Leather and textile feature good flexibility, high strength, and quite easy to get winded while shredding. Flexibility of leather and textile waste determines the optimal shredding principle to shred leather and textile waste is “shear”, while high strength means that the “shear” effect should be powerful.

Harden Machinery Ltd has years of experience in shredding leather and textile, helping hundreds of garment/shoes/curtains/carpets factory to shred and process their production scrap, faulty goods, out-of-date stock, etc.. Harden also services some social associations to manage leather and textile waste in the municipal waste, mainly focusing on two shaft shredder and hydraulic shredder to shred leather and textile.

Features of Harden's Leather and Textile Waste Shredder for Primary Shredding

(Model double shafts shredder TDH1216 and TD912)

l Robust base meant to guarantee stable operation and low noise

l Tempered gears are high-frequency surface hardened

l Casted bearing support has high strength and stability

l Surface hardened wear-resistant alloy guarantees knife life

l Grinded spacers and tempering high-strength shafts

l Electric components of Siemens, Schneider, Omron, and ABB brand

l Double sealing rings for bearing protection

Features of Harden RDF Shredder

(Model single shaft shredder SM3000R)

l Quality reducer with shock absorbing basement

l Precise machining for cutting system

l More cutting surface and output area

l Cutter replacement design

l Slow speed high torque shredding makes low dust and noise operation

l Bulkhead seals protect the shaft bearings

l Two-speed hydraulic system for intelligent feeding integrated with air cooler

Video

Title