Harden Shredder TD912 Serves Bulky Waste Disposal Center in Shanghai

As one

of the leading bulky waste shredder manufacturers in China, Harden company has

received dozens of successful bulky waste shredding disposal cases in both

domestic and overseas markets. With years of shredding experience, Harden's bulky

waste shredding disposal technology is mature and well received in the market.

Bulky waste

includes some bulky furniture, wooden pallets, tree branches, and decoration waste

in the city. If processed properly, wood, leather, and textile can be

recycled as fuel in the incineration plant and metal can be re-melt

to remake steels.

Bulky waste

disposal case information overview

Location: Bulky

waste disposal center, Huangpu district, Shanghai

Center acreage:1500㎡

Harden shredder

model: Harden TD912

Output: 60-120 pieces

per hour

Operators

needed: 2 person

Shredder

installation time: Sept, 2016

Coming with a conveyor and ferrous

separator, Harden bulky waste disposal system was installed in Sept. 2016.

Bulky waste from Huangpu district and Luwan district will be collected to bulky

waste disposal center of Huangpu, Harden bulky waste disposal system shred

bulky waste into qualified size, after shredding. The particles will be transferred to the resource

processing center for further processing.

l Knives are made

of high-strength alloy, no worry of metal crushing

l Knives can be

repaired by welding to reduce the maintenance cost

l Doubleseals,

dust-proof maze, and material baffle for core part protection

l SiemensPLC

automatic controller with overload protection

l Siemensmotor and

quality gearbox ensures high stability

l Conveyortransport

for labor reducing

l Dustpelletizing

system integrated with both shredders and conveyors

l Self-discharging ferrous

separator

l Centralizedautomatic

controller for safe and easy operation

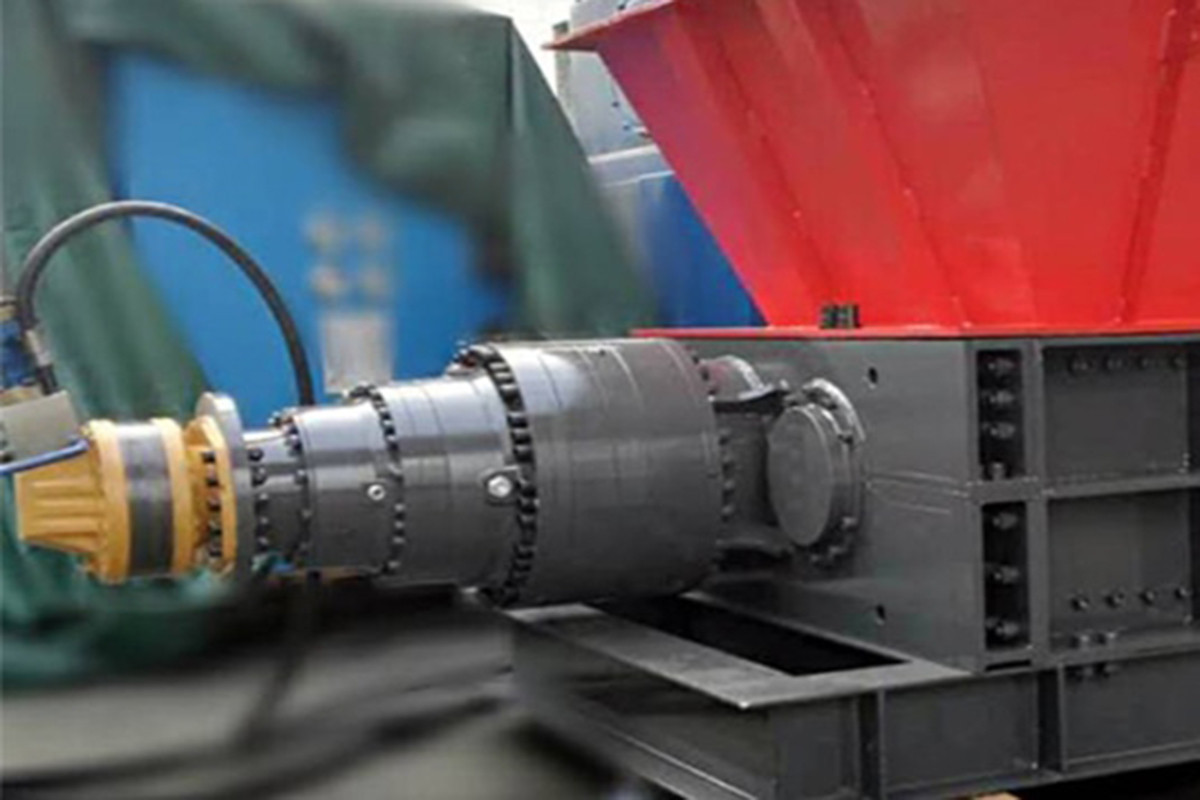

Hydraulic-driven is available at Harden shredding technology

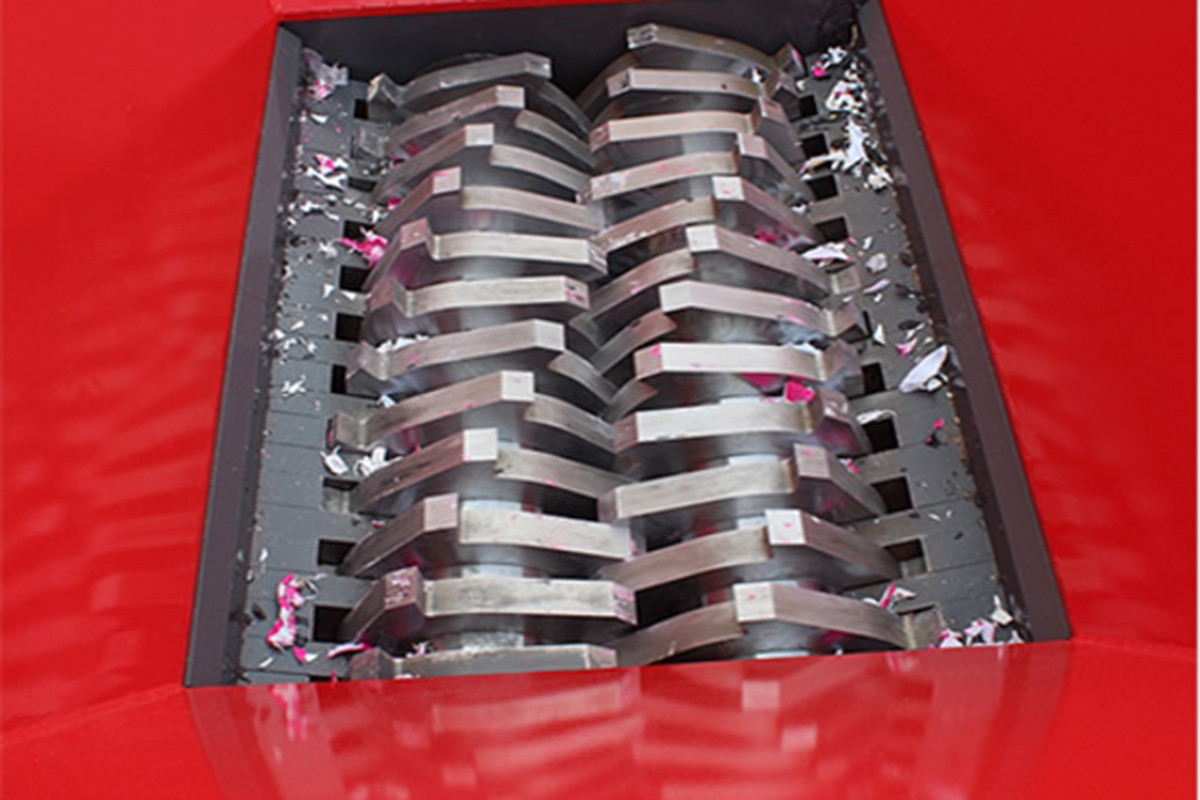

Cutting chamber of TD912

|

Model

|

TD912

|

|

Motor power (KW)

|

75+75

|

|

Cutting chamber (mm)

|

900*1220

|

|

Cutter size (mm)

|

Φ460*50 |

Quantity of blades (pcs) | 20 |

Rotating speed (rpm) | 16/18 |

Hopper opening (mm) | 2000*1400 |

Machine dimension (mm) | 4500*2200*2800 |

Machine weight (Kg) | 10000 |

Output (tons/h) | 10-20 |